Flatbed UV Prints on Acrylic

Flatbed UV Prints on Acrylic

At LCI we make flatbed UV Prints on Acrylic of up to 50″ x 100″ (an oversized 4′ x 8′ sheet) We print direct onto acrylic substrate with a vibrant color, matching most Pantone Colors.

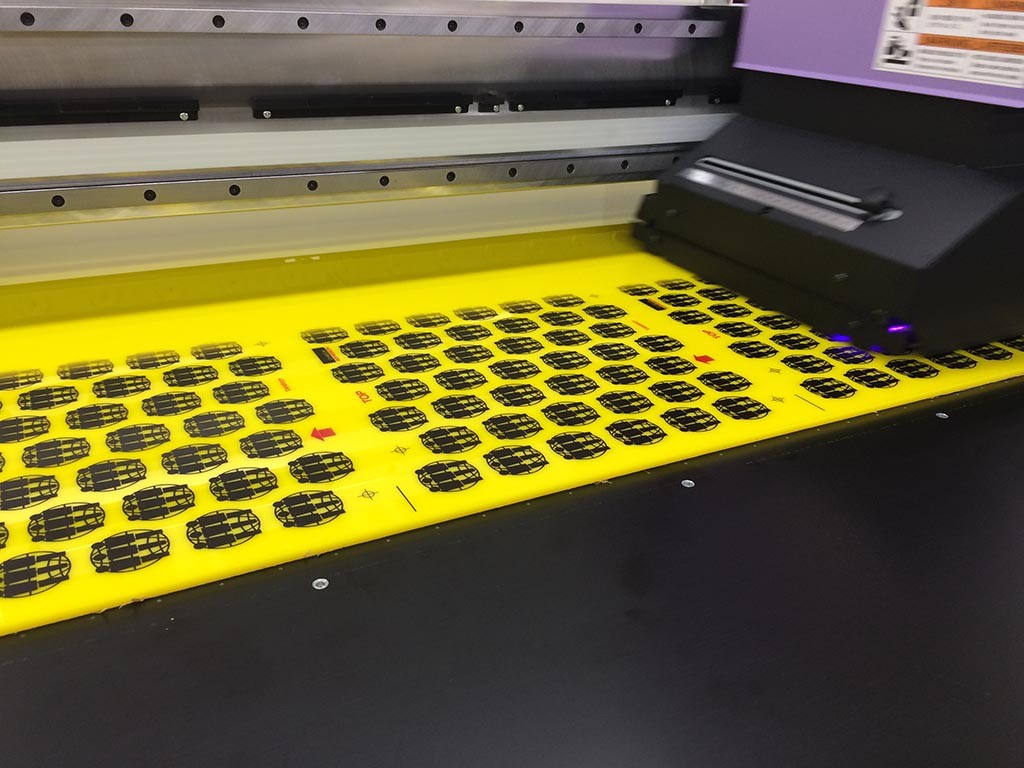

Whether, spot colors, gradients or full color prints, you can be confident we will color match with perfection. On the second picture (of the yellow on black print), we have to lay down white ink before we print the yellow otherwise the black acrylic will show through the yellow. This will give a translucent effect.

Our inks lead the industry for adhesion as well. After the printing process is complete, we laser cut the parts out of the printed sheet using very precise registration.

Frequently Asked Questions:

1. Do I need to supply LCI with a cad file for the project I need produced?

A: A cad file is helpful if you have one but it is not necessary. Our design team can work with you to turn your idea into a finished product.

2. What format files do you work with?

A: Adobe Illustrator, Corel Draw, Adobe Photoshop, AutoCAD, SolidWorks and most other common formats.

3. What information do I need to get a quote?

A: Size of part yo need cut, Type of Material, Thickness of Material and Color. If you don’t know any of this info, we can guide you.

4. Does LCI send a proof before producing work?

A: We always e-mail a proof for your review before running any parts or products.

5. Can LCI produce a sample part before running large orders?

A: Yes! We can make a production sample before large production.

6: Will the ink scratch off of Flatbed UV Prints on Acrylic?

A: No. Our proprietary printing and cutting process leaves ink in tact even after laser cutting through it. Our ink adheres strong and is tough to scratch off.

7: Is a UV Flatbed Acrylic Print durable?

A: Yes. Our inks will not scratch off acrylics.

Need a Quote on a Project?

Either give us a call or e-mail us at the address listed below. We understand that our customers need quick turn around times and our team responds quickly to quote requests to help you with a solution. From pencil sketch to cad file, we can work with just about any file format to make your request into a finished success. All trademarks shown are the property of their respective owners.

Laser Cutting, Inc.

1549 South 38th Street

Milwaukee, WI 53215-1717

Toll Free: 1-800-471-2600

Tel: 1-414-383-2000

Fax: 1-414-383-7447

e-mail: info@lasercuttinginc.us

web url: www.lasercuttinginc.us

Laser Cutting, Inc. serves Chicago with 1 day UPS ground shipping!

Here’s What Our Customers Think of Us:

An absolute pleasure to work with. Provides honest, hard work and is willing to go the extra mile to insure that the customer gets exactly what they want. — Ian Evans

Laser Cutting, Inc performed work for me for nearly 15 years. They are customer focused and very easy to work with. I wouldn’t hesitate to recommend them. — Ron Meyers

We have used Laser Cutting, Inc. for our office signs, they have delivered impressive quality work and a very prompt turnaround time every time. We will definitely continue doing business with them. — Ahide Valdepena

Leave a Reply

You must be logged in to post a comment.

6 Comments

Display General

August 26, 2015How well does your UV ink adhere to Plexiglass and PETG? We have had issues with our previous vendor.

George

August 26, 2015Our inks are formulated and optimized for acrylic, PETG and other plastics. We do adhesion tests on everything we print by making a test print and then slicing it with a razor into tiny strips. Then we scrape the test area with an xacto knife to make sure there is no flaking. Our prints are solid and very durable especially on plastics.

Joe

August 31, 2015Can you print , laser cut, and then heat-bend styrene shelf talkers

George

September 1, 2015We do print styrene. Ink adhesion is at optimum on this substrate and laser cut edges are clean and free of burn. Also styrene can be bent, glued and fabricated.

Joe

August 31, 2015Can you print, cut, and then heat-bend styrene?

George

September 1, 2015Yes. Our inks adhere very well to styrene and when we laser cut it, we get a nice clean edge. Styrene can also be heat bent. We have state of the art heater tables for precise bend configurations.